Waste Disposal: A Comprehensive Guide to Methods, Management, and Environmental Impact

- Jonathan R.

- January 20, 2025

Table of Contents

When the production manager discovered they were spending over $20,000 monthly on waste disposal, he knew something had to change. After implementing a specialized drum compaction system, their disposal volumes dropped by 60%, and costs plummeted.

Waste headaches aren’t limited to chemical producers. From manufacturing plants to research labs, organizations struggle with growing disposal costs and complex regulations. This guide breaks down what actually works in modern waste disposal.

We’ve spent many years helping companies tackle industrial waste challenges. Throughout this guide, we’ll examine proven methods to reduce volumes, cut expenses, and stay compliant without disrupting operations. You’ll find practical strategies whether you’re dealing with everyday industrial waste or navigating hazardous material requirements.

1. The Real-World Impact of Waste Disposal

The numbers tell a compelling story. North American companies produce over 14 million tons of hazardous waste annually. Disposal costs increase nearly 5% each year. Non-compliance penalties average $93,500 per violation.

Behind these figures are businesses making daily decisions about their waste. A 2023 study of industrial facilities found that over a third of materials sent to landfills could have been recycled or compacted. For participating companies, this represented almost $2 million in unnecessary expenses.

For specialized industrial operations, these challenges demand practical solutions. Companies implementing advanced waste reduction technologies see average returns of 125% within three years. Waste compaction delivers particularly strong results for facilities handling chemical containers, contaminated materials, and regulated waste streams.

The following data highlights the significant economic and environmental impact of waste management decisions for industrial facilities.

| Impact Metric | Value | Significance |

| Annual North American hazardous waste production | 14+ million tons | Demonstrates scale of challenge |

| Annual disposal cost increase | ~5% | Rising expense trend |

| Average non-compliance penalty | $93,500 per violation | Financial risk of improper management |

| Recyclable/compactable materials sent to landfill | >33% | Opportunity for improvement |

| ROI on advanced waste reduction technologies | 125% within 3 years | Financial incentive for investment |

2. Types of Waste

Understanding waste types is essential for determining appropriate disposal methods:

2.1 Municipal Solid Waste

Municipal solid waste (MSW) consists of everyday items discarded by the public. This includes:

- Household garbage

- Food waste

- Paper and packaging materials

- Yard trimmings

- Furniture and appliances

- Consumer electronics

2.2 Industrial Waste

Industrial waste is generated by manufacturing and industrial processes, including:

- Chemical byproducts

- Sludges

- Manufacturing residues

- Mining waste

- Agricultural waste

2.3 Hazardous Waste

Hazardous waste contains substances that pose substantial threats to public health or the environment. These materials exhibit characteristics like toxicity, corrosivity, ignitability, or reactivity. Common hazardous waste examples include industrial chemicals, certain paints, batteries, pesticides, medical waste, and electronic components.

2.4 Radioactive Waste

Radioactive waste contains radioactive materials, primarily from nuclear power generation, medical procedures, research activities, and military operations. This waste requires specialized handling due to radiation hazards.

2.5 E-waste

Electronic waste or e-waste includes discarded electronic devices and components. These items often contain valuable materials like gold and copper alongside toxic substances like lead, mercury, and flame retardants.

Understanding waste classification is essential for proper management and regulatory compliance.

| Waste Type | Primary Sources | Common Examples | Management Challenges |

| Municipal Solid Waste | Households, commercial establishments | Food waste, packaging, furniture | Volume, collection logistics |

| Industrial Waste | Manufacturing, production processes | Chemical byproducts, sludges | Specialized handling requirements |

| Hazardous Waste | Industrial/chemical processing, healthcare | Solvents, batteries, pesticides | Regulatory compliance, treatment costs |

| Radioactive Waste | Nuclear power, medical facilities, research | Spent fuel, contaminated materials | Long-term containment needs |

| E-waste | Consumer/business electronics | Computers, phones, appliances | Toxic components, valuable resource recovery |

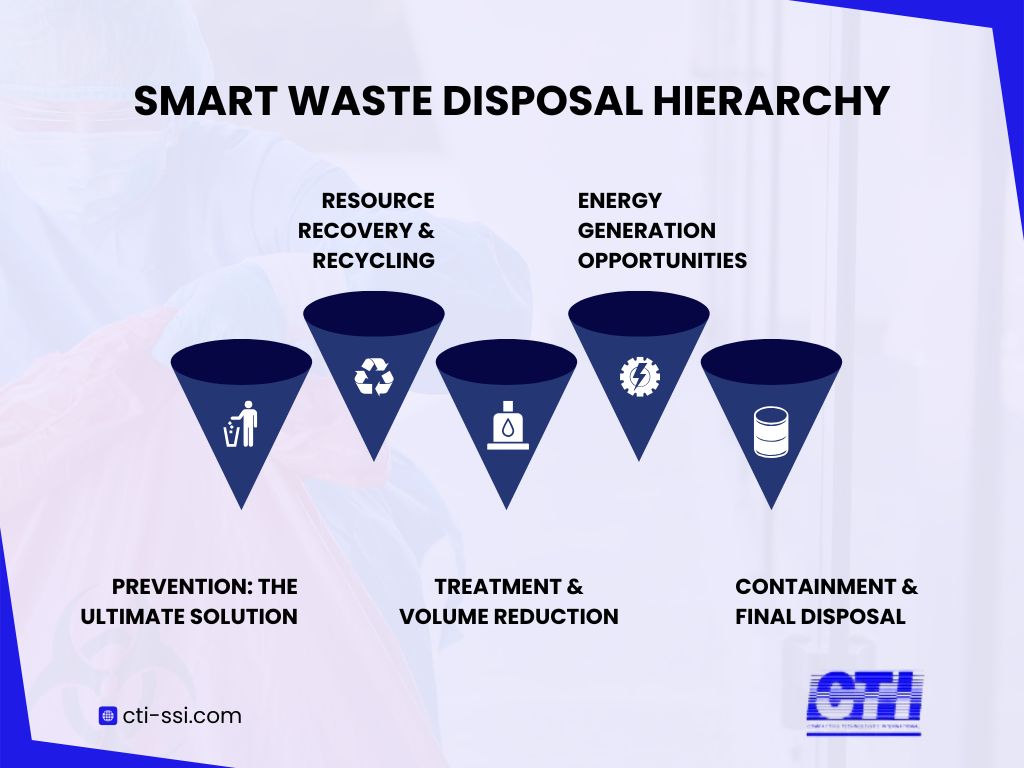

3. Waste Disposal Methods

Various methods exist for disposing of waste, each with specific applications, advantages, and limitations:

3.1 Landfills

Landfills remain the most common waste disposal method worldwide. Modern landfills are engineered facilities designed to isolate waste from the environment until it is safe. They include:

- Liner systems to prevent leakage

- Leachate collection and treatment systems

- Methane collection systems

- Regular monitoring for environmental impacts

While landfills provide a relatively simple disposal solution, they face challenges including limited space, potential groundwater contamination, greenhouse gas emissions, and long-term management requirements.

3.2 Incineration

Incineration involves the combustion of waste materials at high temperatures. Modern incinerators, often called Waste-to-Energy (WTE) facilities, recover energy from the combustion process. Benefits include:

- Volume reduction (up to 90%)

- Energy recovery for electricity or heating

- Destruction of pathogens and toxic compounds

However, concerns include air emissions (though significantly reduced with modern pollution controls), high operational costs, and ash disposal requirements.

3.3 Composting

Composting is a biological process that converts organic waste into nutrient-rich soil amendment. This environmentally friendly method:

- Reduces landfill use

- Creates valuable soil conditioner

- Decreases methane emissions from landfills

- Closes the nutrient cycle

Composting works best for food waste, yard trimmings, and other biodegradable materials but requires proper management to avoid odors and pests.

3.4 Recycling

Waste recycling involves processing used materials into new products. This method:

- Conserves natural resources

- Reduces energy consumption

- Decreases landfill usage

- Creates jobs in the recycling industry

Common recyclable materials include paper, cardboard, glass, metal, certain plastics, and increasingly, construction and demolition waste.

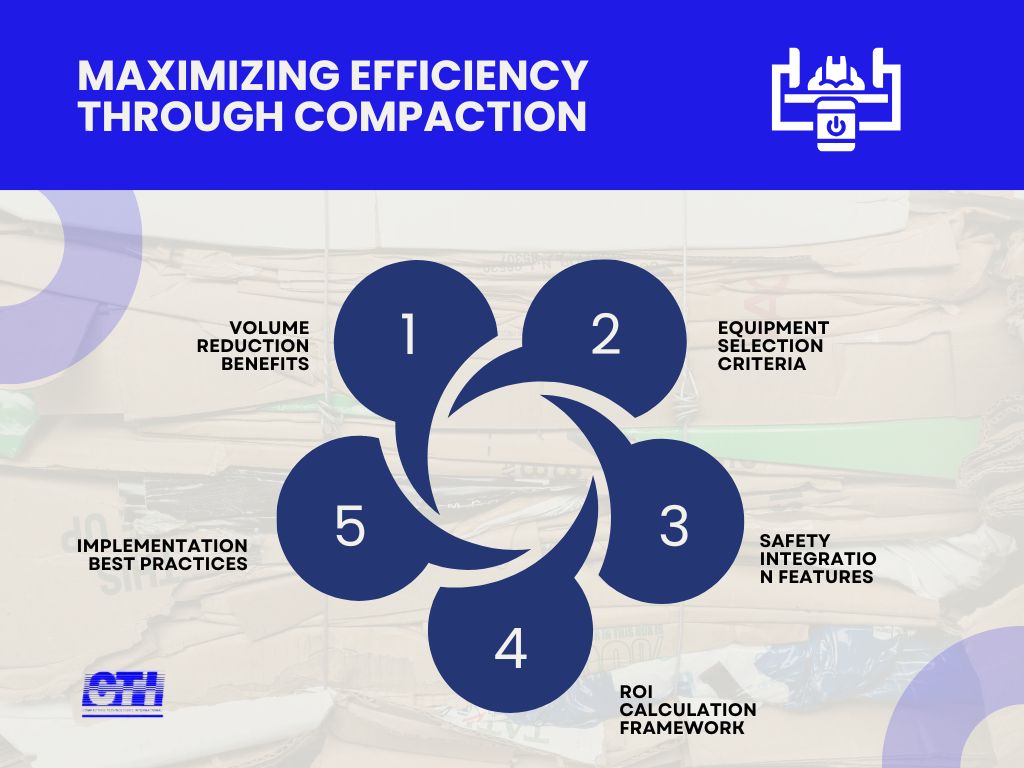

3.5 Waste Compaction

Waste compaction represents a crucial intermediate step in efficient waste management. By reducing waste volume through mechanical compression, compaction systems offer significant benefits:

- Decreased storage space requirements

- Reduced transportation costs

- Lower disposal expenses

- Enhanced waste handling safety

This approach is particularly valuable for garbage disposal in industrial settings and hazardous waste management, where specialized equipment safely compresses materials while containing potential contaminants.

Each disposal method offers distinct advantages for specific waste streams and operational contexts.

| Disposal Method | Volume Reduction | Energy Recovery | Environmental Impact | Relative Cost | Best Applications |

| Landfills | Low | Low-Medium (methane) | Medium-High | Low-Medium | Non-recyclable MSW |

| Incineration | High (90%) | High | Medium | High | Waste with energy value |

| Composting | Medium (50-70%) | None | Low | Low-Medium | Organic waste |

| Recycling | Medium | Medium | Low | Medium | Paper, metals, glass, certain plastics |

| Waste Compaction | High (60-80%) | None | Low | Medium | Industrial containers, contaminated solids |

4. Practical Waste Disposal Guide: From Everyday Items to Industrial Materials

Managing waste properly protects our environment and keeps businesses compliant with regulations. This guide covers disposal methods for common household items and industrial materials alike.

4.1 Household Waste Disposal Solutions

Many everyday items need specific disposal approaches. When figuring out how to dispose of cooking oil, never pour it down drains where it causes plumbing nightmares. Instead, collect it in sealed containers and take it to local recycling centers. The question of how to dispose of paint has different answers depending on type—water-based paints can usually be dried out and thrown away with regular trash, while oil-based varieties need special handling at hazardous waste facilities.

Car owners often wonder how to dispose of old gas or how to dispose of antifreeze that’s gone bad. These automotive fluids create serious environmental problems if they end up in soil or water systems. Most auto service shops accept these materials, as do community hazardous waste collection events held periodically in many towns.

Some bulky household items create unique challenges. Suppose you’re wondering how to dispose of a mattress. In that case, your options typically include scheduling special pickup through your waste service, finding recycling facilities that recover the metal springs and foam, or hiring junk removal services that responsibly handle these awkward items.

4.2 Industrial Waste Management

Manufacturing and processing facilities generate complex waste streams categorized as either hazardous waste or non-hazardous waste. This distinction affects everything from handling procedures to disposal costs.

Liquid waste disposal challenges affect virtually every industry sector. Various types of liquid waste demand tailored treatment approaches:

| Waste Type | Common Examples | Disposal Method | Treatment Technology |

| Non-hazardous liquid waste | Process water, equipment washing | Industrial treatment systems | Settling tanks, biological breakdown |

| Hazardous liquid waste | Industrial solvents, acids | Specialized treatment | Neutralization, carbon filtration system |

| Oily liquid waste | Machine oils, manufacturing residues | Oil-water separation | Mechanical separation, filtering |

| Organic liquid waste | Cooking oil, food processing residues | Biological processing | Bacteria treatment, compost conversion |

| Fuel waste | Old gas, contaminated diesel | Energy recovery | Filtering, re-processing |

Companies specializing in liquid waste removal transport these materials safely between generation points and treatment facilities. Effective liquid waste management requires proper containment, accurate documentation, and strategic planning to control costs while maintaining compliance.

4.3 Hazardous Waste Considerations

Regulatory frameworks define characteristics of hazardous waste based on four properties: ignitable (flash point below 140°F), corrosive (very acidic or alkaline), reactive (unstable under normal conditions), or toxic (harmful when ingested or absorbed). Common types of hazardous waste include:

- Flammable materials including old gas and painting solvents

- Acids and bases that can burn skin or damage materials

- Certain chemicals that react dangerously with water or air

- Materials containing heavy metals, persistent chemicals, or pesticides

Storage typically requires a properly labeled hazardous waste barrel with secure closures and secondary containment systems. The question of where to dispose of hazardous waste usually leads to permitted treatment facilities and transfer stations, information about which is available from local environmental agencies.

4.4 Specialized Waste Streams

Certain items demand particular handling procedures:

- The disposal of propane tanks requires caution due to residual pressure and flammability. Many hardware stores and propane suppliers accept empty tanks for recycling or refilling.

- Wondering how to dispose of light bulbs? Incandescent bulbs can typically go in regular trash, but fluorescent tubes and CFLs contain mercury requiring special handling through hardware store recycling programs.

- When determining how to dispose of a fire extinguisher, first check if it can be recharged. If damaged, professionals must safely depressurize it before the metal components can be recycled.

4.5 Advanced Treatment Technologies

Sophisticated treatment approaches help manage difficult waste streams:

- Activated carbon filtration excels at capturing organic compounds through its porous structure and chemical attraction. This technology proves invaluable for industrial wastewater containing oils, solvents, and other organic pollutants.

- The benefits of carbon filtration systems include:

- Pulling organic compounds from water through adsorption

- Drastically reducing odor-causing compounds

- Improving clarity in processed water

- Stripping chlorine and similar chemicals from solutions

System designs vary between granular beds for large-scale applications and powdered forms for batch treatment processes, depending on volume and contaminant profiles.

4.6 Implementing Effective Waste Management

A comprehensive waste program requires attention to:

- Accurate waste identification through testing and analysis

- Appropriate containers and storage areas for different materials

- Regular training for all staff handling waste materials

- Carefully selected treatment technologies matching waste characteristics

- Thorough documentation meeting all regulatory requirements

- Regular program reviews identifying improvement opportunities

Organizations following these principles typically achieve compliance while controlling costs and environmental impacts.

Remember that rules about how to dispose of various materials differ between jurisdictions. Always verify requirements with local waste authorities before finalizing disposal plans.

5. Safe Storage and Handling

Proper waste storage before disposal is crucial, particularly for hazardous materials. Key considerations include:

5.1 Container Selection

Different waste types require appropriate containment. Standard options include:

- 55-gallon drums for many liquid and solid wastes

- Storage totes for bulk liquids

- Flammable cabinets for combustible materials

- Specialized containers for radioactive or highly toxic substances

5.2 Storage Facility Requirements

Storage facilities must meet stringent requirements under OSHA drum storage requirements and other regulations, including:

- Secondary containment

- Proper ventilation

- Fire suppression systems

- Security measures

- Warning signage

- Hazard identification systems

5.3 Specialized Storage Solutions

For particularly dangerous materials, specialized storage is required:

- Magazine buildings for explosives storage

- Hazmat storage containers for various chemical hazards

- Temperature-controlled units for reactive materials

Proper containment prevents releases and protects workers handling waste materials.

| Container Type | Capacity | Suitable Materials | Safety Features | Regulatory Standards |

| 55-Gallon Drums | 55 gallons (208L) | Most liquids and solids | Corrosion resistance, sealed closures | DOT, UN ratings |

| IBC Totes | 275-330 gallons (1,040-1,250L) | Bulk liquids | Secondary containment frame | UN31HA1, FDA compliance |

| Flammable Cabinets | 12-60 gallons | Flammable liquids | Fire resistance, self-closing doors | NFPA 30, OSHA 1910.106 |

| Hazmat Storage Building | Variable | Multiple hazard classes | Spill containment, fire suppression | EPA, NFPA, OSHA standards |

| Drum Storage Areas | Variable | Various drums | Secondary containment, segregation | 40 CFR 264.175 |

6. Advanced Technologies in Waste Management

Technological innovation continues to transform waste management practices:

6.1 Smart Waste Management

Digital technologies now enhance waste collection and processing through:

- IoT sensors in waste containers

- Optimized collection routing

- Automated sorting systems

- Data analytics for system improvement

6.2 Waste-to-Energy Technologies

Beyond traditional incineration, newer technologies convert waste to energy:

- Gasification: Converting waste into synthesis gas

- Pyrolysis: Thermal decomposition without oxygen

- Plasma arc gasification: Using plasma torches to create extreme temperatures

- Anaerobic digestion: Biological conversion producing biogas

6.3 Compaction Technologies

Specialized compaction equipment significantly reduces waste volume prior to transport or disposal. Modern drum crushers and compactors offer:

- High compaction ratios

- Safer operation with hazardous materials

- Automated systems reducing worker exposure

- Customized solutions for specific waste streams

Emerging technologies enhance efficiency and environmental performance across the waste management lifecycle.

| Technology | Application | Benefits | Implementation Cost | ROI Timeframe |

| IoT Waste Sensors | Collection optimization | 20-30% route efficiency increase | Medium | 1-2 years |

| AI-Powered Sorting | Recycling facilities | 90%+ sorting accuracy | High | 2-4 years |

| Plasma Arc Gasification | Hazardous waste | >95% volume reduction | Very High | 5-8 years |

| Automated Drum Compactors | Industrial containers | 5:1 – 7:1 compaction ratio | Medium | 1-3 years |

| Anaerobic Digestion | Organic waste | Energy production + soil amendment | Medium-High | 3-5 years |

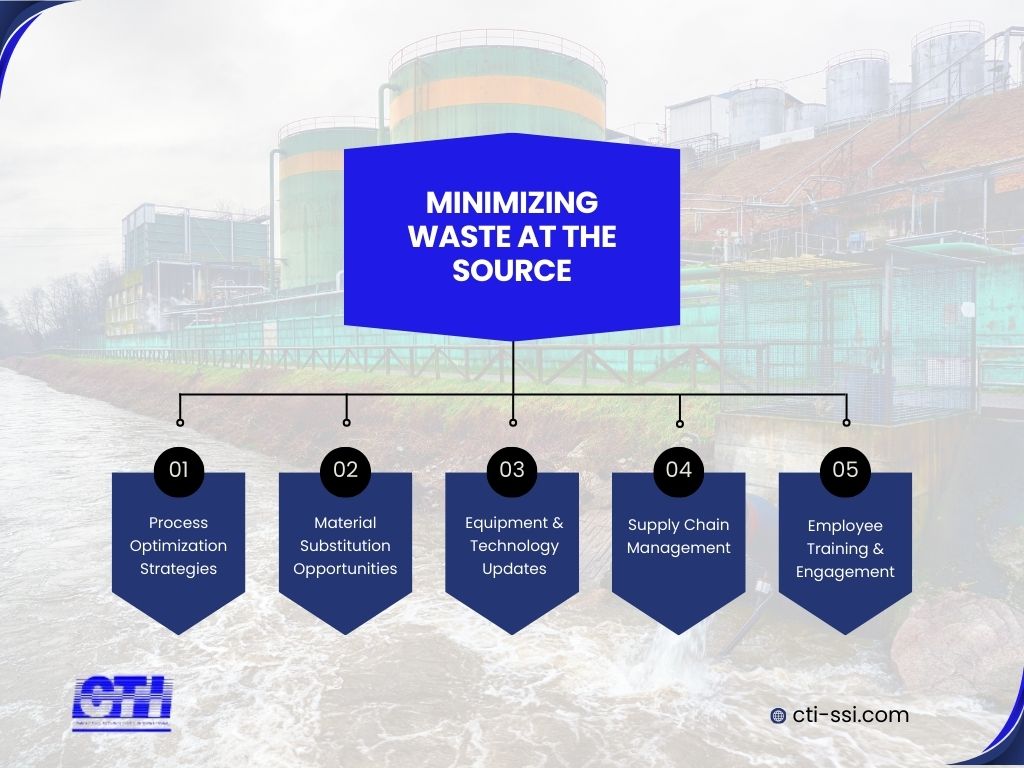

7. Waste Reduction and Minimization

The most effective waste management starts with reducing generation:

7.1 Industrial Waste Minimization

Industries can implement waste reduction through:

- Process optimization

- Materials substitution

- Equipment modernization

- Employee training

- Product redesign

7.2 Circular Economy Approaches

The circular economy concept aims to eliminate waste through:

- Designing products for durability and repairability

- Utilizing renewable resources

- Keeping materials in productive use

- Regenerating natural systems

This approach represents a paradigm shift from traditional “take-make-dispose” models toward regenerative systems.

Prevention and reduction strategies offer the highest environmental and economic returns.

| Strategy | Industry Application | Potential Reduction | Implementation Complexity | Cost Savings Potential |

| Process Optimization | Manufacturing | 15-30% | Medium | High |

| Materials Substitution | Chemical processing | 10-25% | Medium-High | Medium-High |

| Product Redesign | Consumer goods | 20-40% | High | Medium |

| Inventory Management | Pharmaceuticals | 15-25% | Low-Medium | High |

| Closed-Loop Systems | Electronics | 30-60% | High | Very High |

8. Regulatory Framework

Waste management operates within complex regulatory frameworks:

8.1 National Regulations

In the United States, key regulations include:

- Resource Conservation and Recovery Act (RCRA)

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA)

- Clean Water Act

- Clean Air Act

- Toxic Substances Control Act

8.2 International Agreements

Important international waste management agreements include:

- Basel Convention on Transboundary Movements of Hazardous Wastes

- Stockholm Convention on Persistent Organic Pollutants

- Minamata Convention on Mercury

These frameworks establish standards for waste handling, disposal, and international transport.

Navigating the complex regulatory landscape is essential for compliance and risk management.

| Regulation | Jurisdiction | Regulated Materials | Key Requirements | Non-Compliance Penalties |

| RCRA | United States | Hazardous waste | Cradle-to-grave tracking | Up to $100,000/day |

| Basel Convention | International | Hazardous waste shipments | Prior informed consent | Varies by country |

| EU Waste Framework Directive | European Union | All waste | Waste hierarchy implementation | Up to €10M or 5% annual turnover |

| Clean Water Act | United States | Wastewater discharges | NPDES permits | Up to $54,833/day |

| TSCA | United States | Chemical substances | Testing, reporting, restrictions | Criminal penalties possible |

9. Challenges in Waste Disposal

Despite advances, significant challenges remain:

9.1 Developing Countries

Developing nations face particular waste management challenges:

- Limited infrastructure

- Insufficient funding

- Rapid urbanization

- Informal waste collection sectors

- Imported waste from developed countries

9.2 Emerging Waste Streams

New products create waste streams requiring specialized handling:

- Nanomaterials

- Composite materials

- Biodegradable plastics

- Solar panels and wind turbines at end-of-life

- Advanced battery technologies

9.3 Climate Impact

Waste management significantly impacts climate change through:

- Methane emissions from landfills

- Carbon dioxide from incineration

- Transport-related emissions

- Carbon sequestration in composting

Understanding key challenges helps organizations develop more resilient waste management strategies.

| Challenge | Affected Regions/Industries | Impact Severity | Contributing Factors | Emerging Solutions |

| Infrastructure Gaps | Developing countries | Severe | Rapid urbanization, funding limitations | Public-private partnerships |

| Novel Materials | Electronics, renewable energy | Medium-High | Product innovation outpacing disposal solutions | Extended producer responsibility |

| Microplastics | Global ecosystems | High | Non-biodegradable materials, fragmentation | Advanced filtration, biodegradable alternatives |

| Climate Impact | Global waste sector | High | Methane emissions, transportation | Capture technologies, route optimization |

| Hazardous Constituents | Chemical, pharmaceutical | Medium-High | Increasing chemical complexity | Green chemistry, detoxification methods |

10. Optimizing Your Waste Management Approach

Developing an effective waste management strategy requires careful planning:

10.1 Assessment and Analysis

Start with a comprehensive waste audit to:

- Identify waste streams

- Quantify volumes

- Assess current practices

- Identify reduction opportunities

- Calculate disposal costs

10.2 Implementation Strategy

Based on analysis, develop an implementation plan including:

- Waste segregation protocols

- Storage infrastructure

- Staff training programs

- Collection and transport arrangements

- Treatment and disposal methods

- Monitoring and compliance procedures

A systematic approach to waste management optimization delivers measurable operational and financial benefits.

| Optimization Step | Key Activities | Resources Required | Timeline | Expected Outcomes |

| Waste Audit | Characterization, quantification | External consultant, staff time | 1-2 months | Baseline data, prioritization |

| Program Development | Protocols, infrastructure planning | Cross-functional team | 2-3 months | Comprehensive strategy |

| Implementation | Equipment procurement, training | Capital, HR resources | 6-12 months | Operational changes |

| Monitoring | Data collection, compliance verification | Tracking systems, staff | Ongoing | Performance metrics |

| Continuous Improvement | Process refinement, technology updates | Performance data, industry benchmarks | Annual review | Efficiency gains, cost reduction |

11. Building a Comprehensive Waste Management Program

Effective waste management requires a holistic approach:

11.1 Infrastructure Development

Proper infrastructure forms the foundation of effective waste management:

- Safe hazardous waste storage facilities

- Appropriate containment systems

- Treatment technologies suited to waste streams

- Transportation networks

- Final disposal facilities

11.2 Education and Training

Staff training and public education significantly impact program success:

- Proper waste segregation

- Safe handling procedures

- Regulatory compliance requirements

- Emergency response protocols

- Waste reduction opportunities

11.3 Monitoring and Continuous Improvement

Ongoing assessment ensures program effectiveness:

- Regular waste audits

- Compliance evaluations

- Cost analysis

- Technology updates

- Stakeholder feedback

A holistic program integrates people, processes, and technology for sustainable waste management.

| Program Element | Implementation Priority | Stakeholder Involvement | Success Metrics | Common Challenges |

| Infrastructure | High | Facilities, Operations, EHS | Capacity utilization, compliance rates | Capital approval, space limitations |

| Training | High | HR, EHS, All departments | Knowledge assessment scores, incident rates | Staff turnover, content relevance |

| Documentation | Medium | EHS, Legal, Quality | Audit findings, regulatory inspection results | Maintaining currency, accessibility |

| Performance Metrics | Medium | Management, Operations | Waste reduction percentages, cost savings | Data collection, benchmark establishment |

| Community Engagement | Low-Medium | Communications, Management | Perception surveys, stakeholder feedback | Message consistency, transparency |

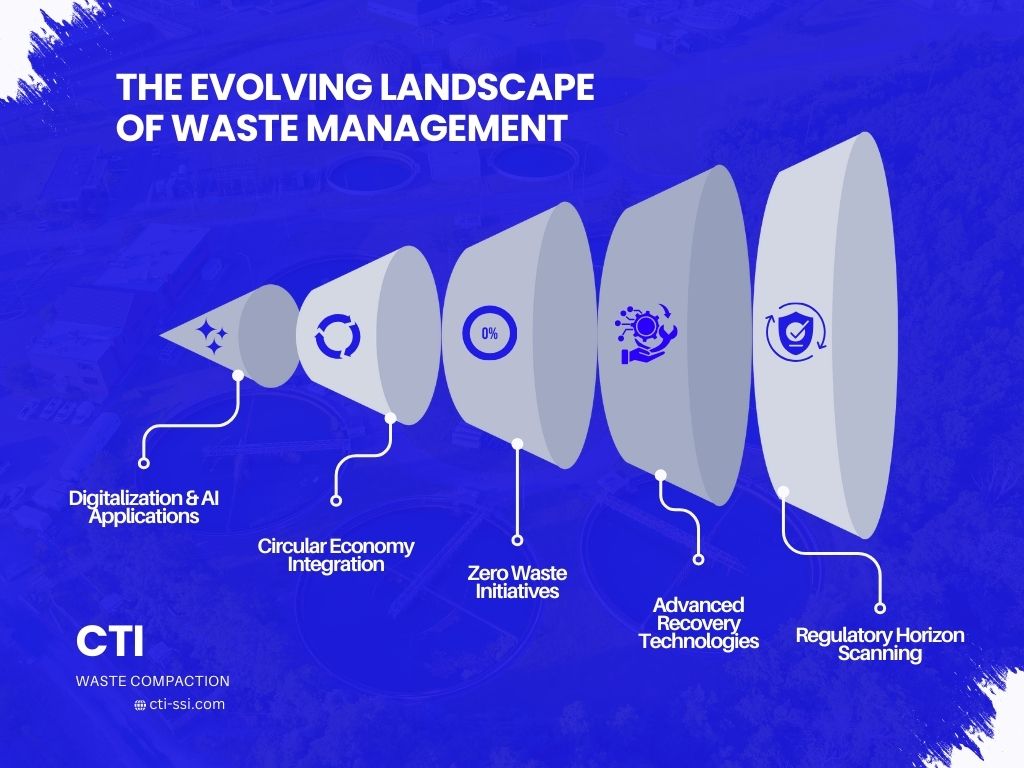

12. The Future of Waste Disposal

Waste management continues to evolve in response to environmental, economic, and social pressures:

12.1 Technological Trends

Emerging technologies reshaping waste management include:

- Artificial intelligence for sorting and optimization

- Advanced materials recovery facilities

- Chemical recycling of plastics

- Microbial solutions for organic waste

- Enhanced landfill mining

12.2 Policy Directions

Policy trends influencing future waste management include:

- Extended producer responsibility

- Landfill bans for recoverable materials

- Pay-as-you-throw systems

- Mandatory recycling programs

- Carbon pricing affecting disposal economics

12.3 Sustainability Integration

Waste management increasingly connects with broader sustainability goals:

- Zero waste initiatives

- Resource efficiency programs

- Climate action plans

- Sustainable development goals

- Environmental justice considerations

Conclusion

Proper waste disposal represents one of society’s most fundamental environmental responsibilities. As waste volumes grow and composition becomes more complex, innovative approaches to waste management become increasingly important.

By embracing comprehensive waste management strategies (including waste reduction, proper segregation, advanced treatment technologies, and responsible disposal) organizations and communities can minimize environmental impact while potentially reducing costs.

For industrial and institutional settings managing hazardous or radioactive waste, specialized solutions like high-efficiency compaction systems offer particular advantages. These technologies can significantly reduce waste volumes, storage requirements, transportation needs, and ultimately disposal costs.

The future of waste disposal lies in viewing waste not as a problem to be eliminated but as a resource to be recovered and reintegrated into production cycles. This paradigm shift, supported by technological innovation, thoughtful policy, and organizational commitment, promises to transform waste management from an environmental challenge into an opportunity for sustainability and economic efficiency.

Ready to transform your waste management approach? Discover how CTI’s advanced compaction technologies can help your organization reduce volumes, cut costs, and enhance safety. View our success stories or learn more about our company to see how we’ve helped organizations like yours tackle complex waste challenges.

Jonathan Reed

Jonathan Reed specializes in writing in-depth, data-driven content on industrial waste management, regulatory compliance, and environmental sustainability. With expertise in hazardous waste disposal, OSHA guidelines, and waste reduction technologies, he provides actionable insights for businesses navigating complex waste management challenges.