Reduce Your Waste with CTI, A Trusted Waste Compactor Manufacturer

CTI is a waste compactor manufacturer that makes strong and reliable machines to help reduce waste and save space. Our compactors make waste management easier and more cost-effective for businesses.

safe

smart

sensible

reliable

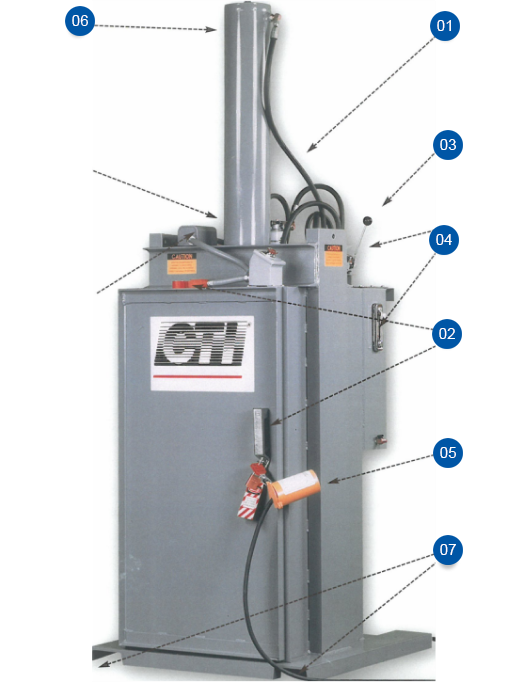

About CTI 8560 Compactor

Choose a Waste Compactor Manufacturer For Safe Compaction and Disposal of Hazardous Material

The CTI 8560 offers the highest compaction ratios and is designed to compact either hazardous or low level radioactive, solid, or saturated wastes. It’s also the easiest to operate and most flexible because it uses a Programmable Logic Controller.

Why Compact?

Reduces the amount of landfill space needed

Disposing hazardous waste is expensive, time consuming and difficult. Less drums reduce your liabilities from accidents. Less drums reduce your liability at landfills which is important with cradle-to-grave responsibilities associated with hazardous waste.

Why use a CTI Compactor?

Customized to safely handle your waste

Waste possesses distinctive characteristics that challenge conventional compaction methods. It is designed to accommodate various types of waste, employing the safest and most efficient crushing techniques tailored to your specific waste profile. Setting it apart from other compactors our equipment is uniquely customized to ensure the safe and effective handling of your waste and its individual attributes.

Standard Features

CTI 8040

Hydraulic System

Safety Interlocks

Controls

Gauges

requirements

compaction Force

Pockets

Standard Features

CTI 8040

Standard Features

CTI 8550

Compaction Chamber

Timer

Quick Load Door

Compaction Force

Hydraulic System

and Platen System

Electrical System

Controls

Interlocks

Disconnect Included

Standard Features

CTI 8550

Standard Features

CTI 8560

logic controller

Compaction Chamber

hydraulic System

and Platen system

Quick Chute

Electrical System

Interlocks

Exterior

Compaction Force

Our most

popular model

popular model

Standard Features

CTI 8560

Our most

popular model

popular model

Optional Features

Within the Safety Storage™ CTI line include, but are not limited to:

Equipped with components to meet the codes governing equipment used in hazardous atmospheres (Class I Division I Group D).

These unique options allow safe and efficient removal of nonexplosive or explosive liquids during compaction, for separate disposal or recycling. A powerful, chemical resistant pump can efficiently remove over 14 gallons of liquid waste per minute. Great for filters, rags soaked

with solvent, containers with liquid residue, etc.

Equipped with fittings to allow for hook-up to the customer supplied dry chemical fire extinguishing system. An electric heat detection circuit activates the user’s fire system.

Equipped with fittings and valves allowing hook-up to the customer’s inert gas supply.

Includes custom hydraulics and a crushing insert that will crush steel drums to approximately 4 inches. Switching from in-drum compacting to drum crushing is easy and safe, and takes only seconds.

This nuclear grade filtration option removes particles to 0.3 microns with 99.97% efficiency.

If Volatile Organic Compounds are present in your waste, this option absorbs them. This system operates when the compactor is in use and

does not allow compaction if the system is blocked.

The stainless steel components (sold separately) allow for easy cleanup and decontamination. Recommended for corrosive or radioactive applications.

Learn how a CTI compactor from Safety Storage Inc. can reduce your disposal costs now!

Success Stories

how much have people benefited?

“We’re saving $170,000 a year in disposal costs.”

Fortune 100: Aerospace Company

“Over 65% decrease in disposal costs.”

Major University

“75% decrease in disposal costs.”

Biomedical Company

“We went from $60,000 a year in disposal costs to $7,000 per year since getting the CTI PRO.”

Aircraft Component Manufacturer

“In the 18 months since the CTI PRO arrived, we’ve saved over $50,000 on disposal costs.”