The Role of Temperature-Controlled Buildings in Industrial Storage

- Jonathan R.

- August 27, 2024

Table of Contents

Industrial storage requires precision. Temperature-controlled buildings play a vital role and are of immense insignificance. Read on to discover why they are essential.

The Basics of Temperature-Controlled Buildings

Temperature controlled buildings maintain consistent temperatures, which is crucial. Many industries rely on these buildings, including food, pharmaceuticals, and electronics.

Food Industry Needs

The food industry demands precise temperature control. Fresh produce needs cool environments, and frozen goods must stay frozen. Improper storage can lead to spoilage, which means lost revenue and safety risks for consumers.

Temperature-controlled buildings prevent these issues. They ensure food remains safe and maintain quality from farm to table. Refrigeration units keep temperatures stable. Monitoring systems alert staff to changes.

Pharmaceuticals Depend on Stability

Pharmaceuticals are sensitive. Temperature fluctuations can degrade them. This degradation reduces effectiveness. In some cases, it can make medications harmful.

Temperature-controlled buildings protect these valuable products and provide the stable environments necessary. Consistency is key from production to distribution, and this protection ensures patients receive safe, effective medications.

Electronics Require Specific Conditions

Electronics is another industry that benefits. Temperature swings can damage components. High temperatures can cause failures. Cold temperatures can cause brittleness. Both scenarios lead to product failure.

Temperature-controlled buildings provide the solution. They maintain optimal conditions. This protection extends product life. It also reduces warranty claims and returns.

How Temperature Controlled Buildings Work

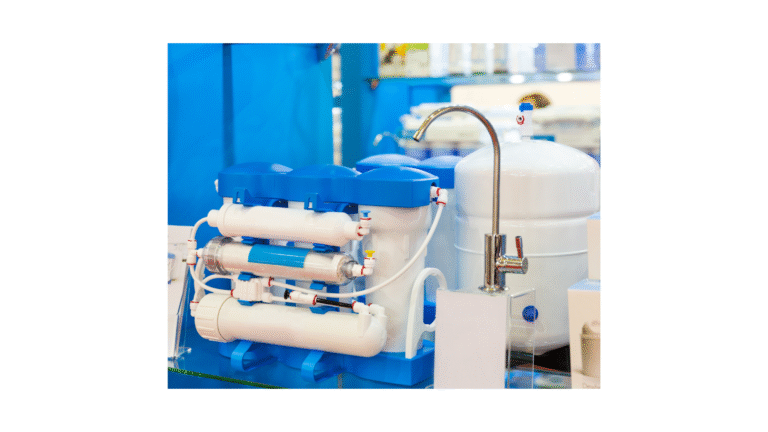

These buildings use advanced technology. Refrigeration systems are central and regulate the internal climate. Sensors monitor conditions constantly, and if temperatures deviate, the systems adjust.

Insulation is crucial, too. It prevents external conditions from affecting internal temperatures, reducing the load on refrigeration systems and improving energy efficiency.

Benefits Beyond Preservation

Temperature-controlled buildings offer more than product preservation. They provide operational benefits, including energy efficiency. Advanced systems use less energy, reducing operational costs.

They also enhance safety. Consistent temperatures reduce risks. Spoiled food and degraded medications are safety hazards, and preventing these issues is a critical benefit.

The Role of Safety Storage Inc.

Safety Storage Inc. is a leader in this field. They specialize in temperature-controlled buildings and offer solutions for various industries. They understand the importance of precision and design systems to meet specific needs.

Their buildings use cutting-edge technology. This ensures reliability. It also ensures efficiency. Safety Storage Inc. prioritizes customer satisfaction. They provide ongoing support and maintenance.

Case Studies: Success in Action

Several companies have benefited from Safety Storage Inc. One example is a major food distributor. They needed reliable cold storage, and spoilage was a significant issue. Safety Storage Inc. provided a solution, reducing spoilage, which led to increased profits and customer satisfaction.

Another example is a pharmaceutical company. They needed consistent temperature control, and their products were sensitive to fluctuations. Safety Storage Inc. delivered a tailored solution. The result was improved product stability, which ensured patient safety and reduced liability.

Challenges and Solutions

Implementing temperature-controlled buildings presents challenges. Initial costs can be high. However, the benefits outweigh these costs. Energy efficiency leads to long-term savings, and reduced spoilage and product failure also contribute.

Maintenance is another challenge. Advanced systems require regular upkeep. Safety Storage Inc. addresses this with comprehensive service plans. They provide regular maintenance and support, ensuring systems operate at peak efficiency.

Future Trends in Temperature-Controlled Storage

The future looks promising. Advances in technology will enhance these buildings. Smart systems will become more prevalent and offer greater precision and efficiency.

Sustainability is another trend, and green technologies will reduce environmental impact. Many companies are making this a growing priority.

Conclusion

Temperature-controlled buildings are essential. They ensure product quality and safety. They offer operational and financial benefits. Industries from food to electronics rely on them.

Safety Storage Inc. leads the way. Their expertise and technology are unmatched. Consider their services for your storage needs.

We invite you to engage with us. Share this post with your network. Comment below with your thoughts. Explore Safety Storage Inc.’s solutions. Together, we can achieve precision and safety in storage.

Read More:

Industrial Applications

Jonathan Reed

Jonathan Reed specializes in writing in-depth, data-driven content on industrial waste management, regulatory compliance, and environmental sustainability. With expertise in hazardous waste disposal, OSHA guidelines, and waste reduction technologies, he provides actionable insights for businesses navigating complex waste management challenges.