Industrial Drum Crusher for Hazardous Waste Management

CTI manufactures heavy-duty drum crushers designed to safely compact hazardous waste inside 55 gallon drums while crushing empty drums for disposal. Our patented Zero Tolerance Compaction Chamber delivers up to 60,000 lbs of compaction force, reducing disposal costs by 65-75% while maintaining full EPA and OSHA compliance. Trusted by Fortune 100 aerospace companies, major universities, and military installations.

Get Your Free Drum Crusher Quote

Complete the form below and our team will contact you within 24 hours to discuss your hazardous waste compaction needs and provide a customized solution.

Massive Cost Savings

Reduce disposal costs by 65-75% through superior compaction ratios. Our customers save between $50,000-$170,000 annually on hazardous waste disposal fees.

Maximum Safety Compliance

EPA and OSHA compliant design with safety interlocks, enclosed systems, and minimal operator exposure. Meets Class I Division I Group D standards for hazardous atmospheres.

Dual Functionality

Compact hazardous waste inside drums AND crush empty 55 gallon drums to 4 inches. Quick conversion between modes maximizes equipment utilization.

The Safest, Most Reliable Drum Crusher for Industrial Hazardous Waste

Patented Zero Tolerance Technology

Our completely enclosed compaction chamber provides full drum support to minimize distortion while containing all volatile vapors, dusts, and liquids in compliance with EPA and OSHA regulations.

Programmable Logic Control

Advanced microprocessor controls monitor compactor status, optimize cycle times, and include hold-down cycles that destroy waste springback for maximum compaction results.

6-12 Month Payback Period

Our customers report average payback periods of just 6-12 months through dramatic reductions in drum count, disposal fees, transportation costs, and liability exposure.

GSA & DLA Approved

As a recognized GSA and DLA supplier, CTI drum crushers meet the stringent requirements of military and government facilities worldwide.

55 Gallon Drum Crusher Models

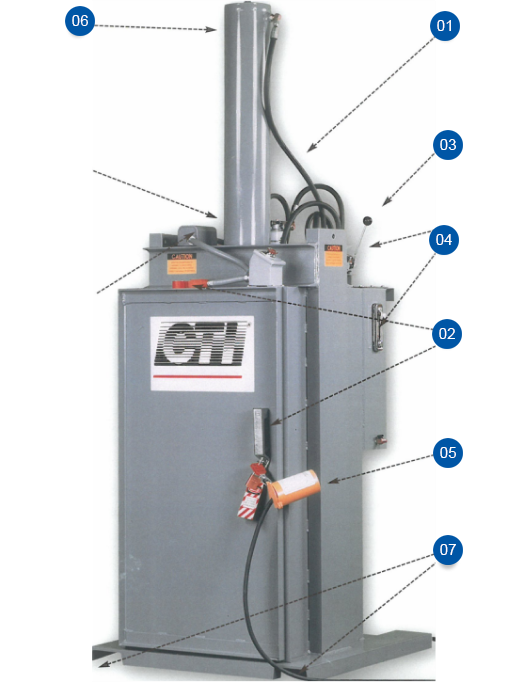

CTI offers three drum crusher models engineered for different operational needs and waste stream requirements. Each model features our signature safety-first design with customizable options for hazardous atmospheres, liquid extraction, fire suppression, and specialized filtration systems.

Built for Hazardous Industrial Waste

CTI drum crushers are the industry standard for facilities managing hazardous chemicals, low-level radioactive materials, contaminated rags and filters, solvent-soaked waste, and materials with liquid residue. Our equipment safely handles what generic compactors cannot—flammable liquids, explosive atmospheres, corrosive materials, and radioactive waste—all while maintaining complete regulatory compliance.

Every CTI drum crusher can be equipped with specialized features including explosion-proof components, chemical-resistant liquid extraction pumps, fire suppression system integration, inert gas purging, HEPA filtration to 0.3 microns, VOC absorption systems, and stainless steel construction for corrosive environments.

Proven Results Across Industries

“We’re saving $170,000 a year in disposal costs.”

Fortune 100: Aerospace Company

“Over 65% decrease in disposal costs.”

Major University

“75% decrease in disposal costs.”

Biomedical Company

“We went from $60,000 a year in disposal costs to $7,000 per year since getting the CTI PRO.”

Aircraft Component Manufacturer

“In the 18 months since the CTI PRO arrived, we’ve saved over $50,000 on disposal costs.”

Furniture Manufacturer

“In the 18 months since the CTI PRO arrived, we’ve saved over $50,000 on disposal costs.”

Furniture Manufacturer

Standard Features

CTI 8040

Hydraulic System

Safety Interlocks

Controls

Gauges

requirements

compaction Force

Pockets

Standard Features

CTI 8040

Standard Features

CTI 8550

Compaction Chamber

Timer

Quick Load Door

Compaction Force

Hydraulic System

and Platen System

Electrical System

Controls

Interlocks

Disconnect Included

Standard Features

CTI 8550

Standard Features

CTI 8560

logic controller

Compaction Chamber

hydraulic System

and Platen system

Quick Chute

Electrical System

Interlocks

Exterior

Compaction Force

Our most

popular model

popular model

Standard Features

CTI 8560

Our most

popular model

popular model

Is a CTI Drum Crusher Right for Your Facility?

If your facility generates hazardous waste in 55 gallon drums and faces disposal costs exceeding $50,000 annually, a CTI drum crusher delivers proven ROI within 6-12 months while dramatically reducing safety risks and regulatory liability.

Aerospace & Aircraft Manufacturing

Facilities with painting, coating, and finishing operations generating waste filters, contaminated rags, solvent-soaked materials, and containers with chemical residue. CTI compactors handle volatile organic compounds safely while reducing drum count by 75%.

Pharmaceutical & Biomedical Companies

Research facilities and manufacturing plants managing active pharmaceutical ingredients, contaminated laboratory waste, biological materials, and hazardous chemical waste requiring complete containment and regulatory compliance.

Semiconductor & Electronics Manufacturing

Clean room operations and manufacturing facilities handling specialized chemicals, contaminated process materials, and electronic component waste requiring precision compaction and contamination control.

Military & Defense Installations

Naval vessels, military bases, and defense contractors managing shipboard hazardous waste, weapons maintenance materials, and classified waste streams requiring GSA/DLA approved equipment with maximum security features.

Nuclear & Radioactive Waste Facilities

Power plants, research reactors, medical facilities, and industrial radiography operations managing low-level radioactive waste where volume reduction directly impacts disposal costs exceeding $2,000 per barrel.

Chemical & Manufacturing Plants

Industrial facilities with painting operations, chemical processing, metal finishing, or manufacturing processes generating hazardous waste streams requiring customized compaction solutions for specific material characteristics.

Find out how much you can save with a CTI drum crusher customized for your specific waste stream.

Frequently Asked Questions About CTI Drum Crushers

Get answers to common questions about drum crusher operations, safety features, regulatory compliance, and cost savings.

CTI customers typically achieve 65-75% reduction in disposal costs with documented savings ranging from $50,000 to $170,000 annually. The average payback period is 6-12 months. Savings come from reduced drum count, lower transportation costs, decreased landfill fees, and minimized liability from fewer hazardous material containers. Exact savings depend on your current waste volume, disposal costs, and waste stream characteristics.

CTI drum crushers are specifically engineered for hazardous materials including low-level radioactive waste, flammable liquids, contaminated filters and rags soaked with solvents, drums with liquid residue, saturated waste materials, corrosive chemicals, and materials in hazardous atmospheres. Our equipment is customized to safely handle the unique characteristics of your specific waste stream with optional features like liquid extraction, fire suppression, and explosion-proof components.

Yes, all CTI drum crushers are fully EPA and OSHA compliant as required for each application. Our equipment effectively contains all volatile vapors, dusts, and liquids in compliance with environmental and safety regulations. We’re also GSA and DLA approved suppliers, and our equipment can be configured to meet Class I Division I Group D standards for hazardous atmospheres. Our safety features include pressure relief valves, door interlock systems, and complete enclosure of all hazardous materials during compaction.

CTI drum crushers are designed for standard 55 gallon steel drums and can be quickly sized and converted to accommodate various drum or pail dimensions. The crushing feature works with any drum size up to 55 gallons, while the compacting feature is optimized for 55 gallon drums. We can customize equipment for your specific container requirements including 30 gallon drums, fiber drums, and other specialized containers.

CTI offers extensive customization including explosion-proof components for Class I Division I Group D atmospheres, chemical-resistant liquid extraction pumps removing 14 gallons per minute, fire suppression system integration with heat detection, inert gas purging systems, drum crushing inserts (crushes drums to approximately 4 inches), HEPA filtration removing 99.97% of particles to 0.3 microns, VOC absorption systems, and complete stainless steel construction for corrosive or radioactive applications.

CTI’s patented Zero Tolerance Compaction Chamber is completely enclosed and provides full support to the drum during compaction, minimizing potential damage or distortion. This design ensures perfect drum positioning under the platen, contains all volatile materials, and prevents operator exposure to hazardous waste. The enclosed system maintains EPA and OSHA compliance while delivering maximum compaction efficiency and safety.

Compaction cycle time varies by model and waste characteristics but typically ranges from 30-60 seconds per cycle. The CTI 8560’s programmable logic controller optimizes cycle times for your specific waste stream while including hold-down cycles that help destroy waste springback for maximum compaction results. Drum crushing operations are similarly efficient, allowing facilities to process significant volumes throughout the workday.

Yes, with proper configuration. CTI drum crushers can be equipped with anti-deflagration devices for additional protection when compacting drums that stored hazardous flammable or combustible chemicals. Our equipment can meet Class I Division I Group D standards for hazardous atmospheres and includes options for fire suppression system integration and inert gas purging to safely handle volatile materials while maintaining complete containment.

CTI drum crushers are engineered for durability and minimal maintenance. Our energy-efficient two-stage hydraulics require only 12 gallons of fluid and prolong component life. Regular maintenance includes routine inspection of hydraulic fluid levels, safety interlock testing, and periodic inspection of the platen and guide rods. All electrical and hydraulic components are enclosed in stainless steel for protection and easy cleanup. We provide comprehensive training, maintenance documentation, and technical support to ensure long-term reliable operation.